Bio concept : Environmental protection and a commitment to sustainable development in general have always been among our key concerns, even before they became the latest buzzwords. That is why at ETESIA, we have developed our own philosophy called Bio Concept.

Two major areas are concerned

Our production Plant

- 100 % of our waste undergoes selective sorting, 0% of it internally, with the use of separate skips for steel, aluminium, cardboard, wood, accumulators and batteries.

- Manufacturing in Europe has positive aspects for a sustainable development

- Environmental impact related to transport is considerably lower than for a machine produced in Asia or in the USA as it is the case for most of our competitors.

- Positive social and economical impact thanks to the safeguarding of employment and industrial know-how in France.

- A GHG Assessment is underway (Green House Gas). This assessment takes into account energy consumptions of the production plant, the refrigerants and the transportation modes. It helps the company which produces it to identify where, when and how it will be able to save energy and to pollute less.

Our machines

- Record longevity of ETESIA : durable machines. For example, after 20 years of good and faithful services, some Hydro 100 machines are still in operation.

- A range of mowers adapted to the differentiated management requirements of today’s customers. The Hydro 124D machine is the perfect illustration of the versatility of the ETESIA Ride-on mowers.

- Development of new environmentally friendly engines.

Learn more about our customers requirements

to help us make the right choices

Does this approach correspond to an expectation?

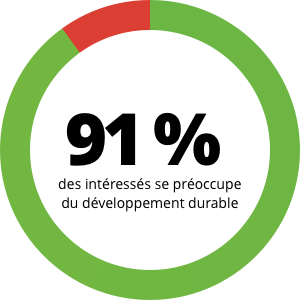

A Survey from 300 people responsible for the green areas of French cities listing more than 5000 inhabitants:

91 % express their concern for:

the integration of sustainable development into their policy of:

• Biodiversity

• Water protection

• Reduction of noise

• Reduction of CO2 emissions

• The practice of the differential management

Study realized by AGRINOVA

On which phase has ETESIA to act to reduce its environmental impact?

To answer this question, we carried out a study of the environmental impact of our 80cm ride-on mower Family by Bureau Veritas CODDE (Life Cycle Assessment and Ecodesign) http://www.codde.fr/

Distribution of the environmental impacts of the thermal lawnmower on its life cycle

- MANUFACTURE phase 9%, Average

- COMMERCIAL phase 1%, Average

- USEAGE phase 85%, Average (incl. 90% of fuel consumption)

- END OF LIFE phase 5%, Average

It clearly shows that it is the usage phase (85%) which has the biggest impact on the environment and more particularly the fuel consumption (90%).

This is why; the efforts of our engineers were dedicated towards our clean engine options for ride-on mowers.

The ETESIA’s BIOCONCEPT rewarded

- Eco-trophies of the framework of life 2010

Coup de coeur of the jury for the electrical mower. Bronze trophy for « Bioconcept Eco Management » - The 2010 Communication Award

Winner (5th) in the category “best action of environmental communication. - Trophy Cape ‘ tronic 2011

Designated in the eco-innovation category - Top Innovation “Salon Vert” 2012

The M2E distinguished in the Construction and maintenance of green spaces category

But the best reward, it is the confidence of the users. For example, the football club of Forest Green Rovers in England is an ETESIA machine owner. The club possesses a bio diesel Version of the Hydro 124D (equipped with a scarifier), an electric bahia M2E and a Robot mower ETm 105.

ETESIA’s vision of its future market is one where business and environmental protection are ultimately reconciled.

ETESIA’s commitment is taking concrete form with its new green engines and also through the versatility of the range, making it possible to apply several mowing techniques and thus enabling differential management.